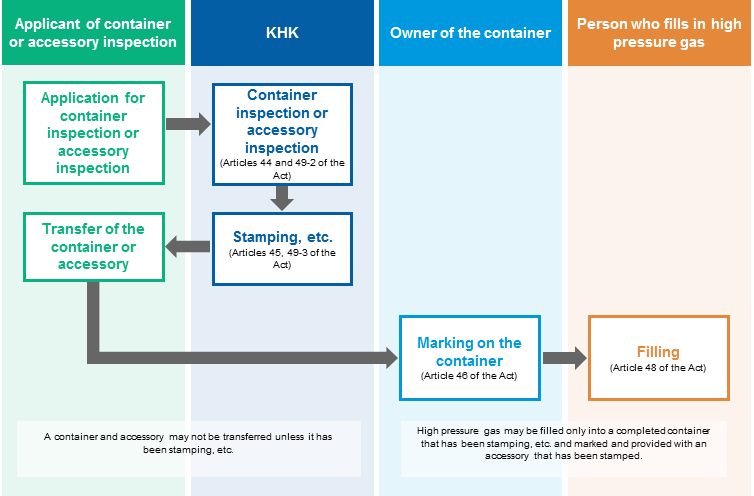

Overview of the system

The inspection is mandatory for manufacturers or importers of accessories (valves, safety devices, emergency shutoff devices, etc.) to be provided on containers, and is conducted pursuant to Paragraph 1, Article 49-2 of the High Pressure Gas Safety Act (the “Act”).

An accessory may not be transferred or handed over unless it has successfully passed the inspection and has been stamped. Also, an accessory that has been stamped must be provided on a container when filling high pressure gas into the container.

Standard process flow from production to filling

Subject of inspection

Manufacturers or importers of accessories are subject to the inspection.

[Supplementary information]

When importing to Japan an accessory produced by an accessory manufacturer outside of Japan, the application for accessory inspection thereof needs to be filed by the importer in Japan.

For details on the accessory inspection procedures, please consult KHK through the importer in Japan.

Inspection description

The inspection is conducted pursuant to the relevant regulations and manuals, through document review and witness inspection including Batch Test for confirming the product conformity and for confirming that the technical standards laid out in the relevant regulations have been met. (For certain types of accessories, Type Approval Test is conducted for confirming the design conformity prior to the Batch Test.)

[Supplementary information]

The accessory inspection is conducted pursuant to the standards laid out in the regulations related to the Act.

Therefore, the accessory to be inspected by the accessory inspection needs to conform to the standards.

For details about the standards, please consult KHK through the importer in Japan.

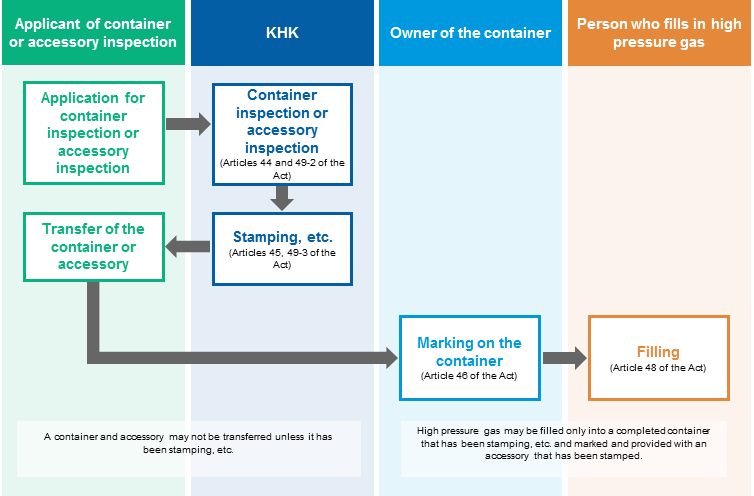

Standard process flow of inspection