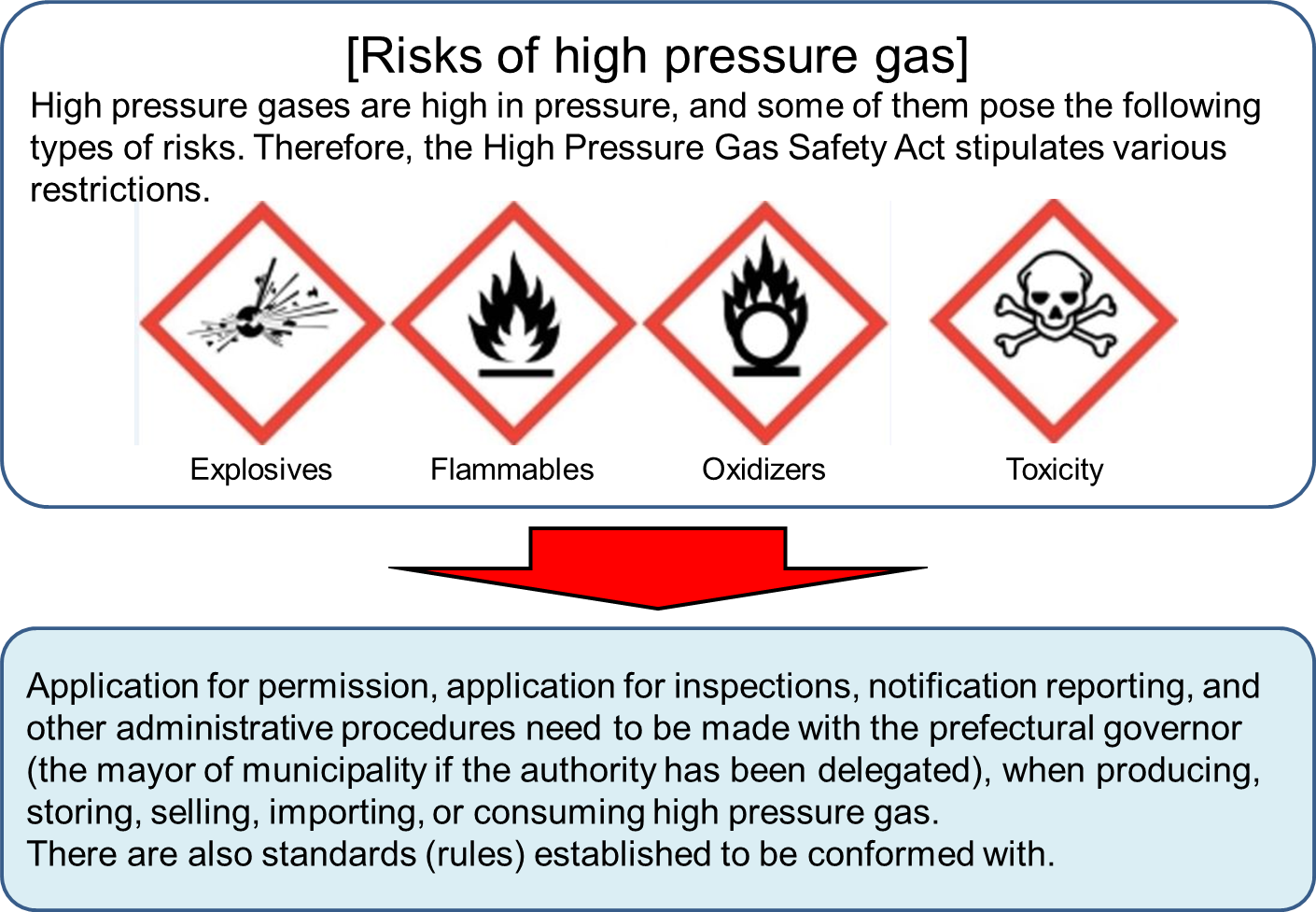

When producing, storing, selling, importing, or consuming high pressure gas, applications for permission and inspection, notification reporting, and other administrative procedures need to be completed with the prefectural governor (the mayor of the municipality if the authority has been delegated).

This page gives an overview on the regulations relating to the administrative procedures for production, storage, sale, consumption, and import to which the High Pressure Gas Safety Act (the “Act”) applies.

Click here for the regulations pursuant to the Act on the Securing of Safety and the Optimization of Transaction of Liquefied Petroleum Gas (the “LPG Act”).

(Note) Production of high pressure gas for refrigeration is not dealt with on this page.

Risks of high pressure gas and legal regulations

Main administrative procedures and their meaning

| Category |

Meaning |

Synonyms |

| Permission |

To specially permit an action that should not be made (lifting of prohibition on general matters) |

Approval, accreditation, license, patent |

| e.g., permission on production of high pressure gas, permission on establishment of Class 1 Storage Place, permission for a change |

| Authorization |

An agreement by an administrative organ on the designated matter |

Permission, approval, certification |

| e.g., authorization of LPG Safety Service Code |

| Registration |

To record the designated matters on books of an administrative organ |

Registration (with a registry office) |

| e.g., registration of a container reinspection station, registration of an LPG Dealer |

| Accreditation |

Confirmation of a certain fact by an administrative organ |

Confirmation |

| e.g., accreditation of Accredited Completion and Accredited Safety Inspection Executors, accreditation of Specified Equipment, accreditation of a Safety Agency |

| Notification report |

To notify the designated matter to an administrative body (prior notification, after-the-fact notification) |

Statement, report |

| e.g., notification report on production, storage and sales of high pressure gas, notification report on Specific High Pressure Gas Consumer, notification report on Hazard Prevention Rule, notification report on appointment or dismissal of Safety Controller, etc., notification report on a minor change, notification report on suspension, notification report on succession, notification report on an accident, notification report on abolition |

| Inspection |

To confirm the conformity to specifications and standards and conduct investigation for ensuring law enforcement |

Verification, certification, auditing, investigation |

| e.g., Completion Inspection, Safety Inspection, import inspection, container inspection, accessory inspection, Designated Equipment Inspection, entrance for inspection |

Overview on the regulations relating to high pressure gas production

What does it mean by high pressure gas production?

High pressure gas production refers to artificially creating a high pressure gas state by compression, liquefaction, or other means, and is not limited to manufacture of high pressure gas products.

| Act of production |

Specific examples |

Equipment examples |

| (1) To bring about a high pressure gas state by changing the pressure. (The high pressure gas state results after compression or depressurization) |

Compression: 0 Pa to 5 MPa, 5 MPa to 30 MPa

Decompression: 10 MPa to 2 MPa

(Not the act of production) 15 MPa (gas) to 0.3 MPa (gas) |

Compressor, pump, pressure reducing valve, accumulator, CE |

| (2) To bring about a high pressure gas state by changing the state of the matter. (The high pressure gas state results after liquefaction or gasification) |

Condensation: 2 MPa (gas) to 2 MPa (liquid)

Gasification: 2 MPa (liquid) to 2 MPa (gas)

(Not the act of production) 0.5 MPa (liquid) to 0.5 MPa (gas) |

Condenser, carburetor, distillation tower |

| (3) To fill high pressure gas into a container. (Stipulated in Article 5 of the Act; the high pressure gas state results in the container) |

High pressure gas results as the pressure rises, for example from 0 Pa to 14.7 MPa, in the container after filling. |

Filling using a compressor, transfer and filling from a main container to a sub container |

| (4) Generating high pressure gas |

Hydrogen + Nitrogen → Ammonia

High pressure gas in a form of liquefied gas is generated when liquids that were originally of a temperature below the boiling point are heated to above the boiling point. |

Chemical reactor, separator, heat exchanger, heater |

*If high pressure gas results after compression, liquefaction, gasification or decompression, the act falls in the category of high pressure gas production.

High pressure gas production plant (examples)

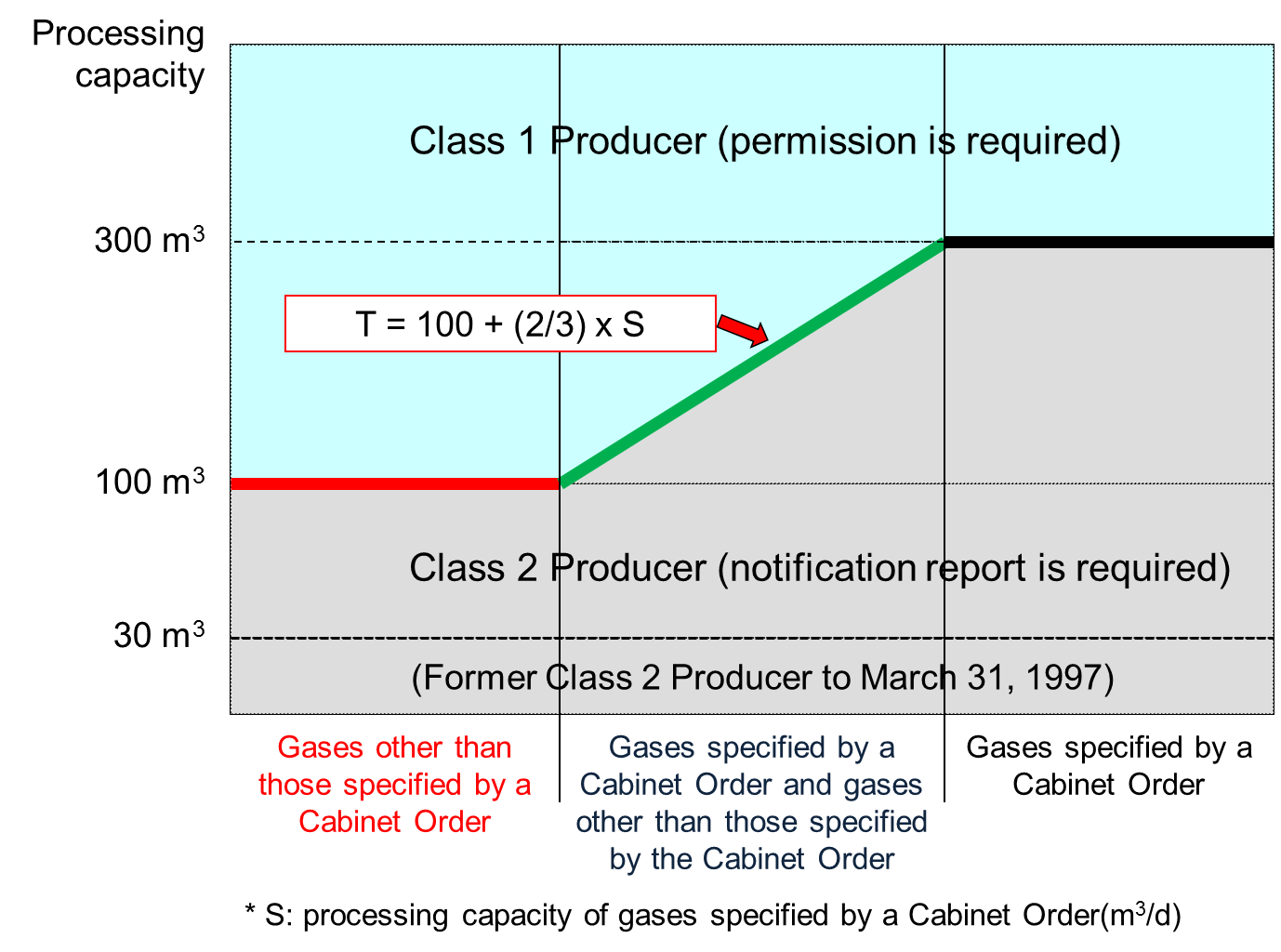

Categories of the permission and notification report for high pressure gas production

- Gases specified by a Cabinet Order include helium, neon, argon, krypton, xenon, radon, nitrogen, carbon dioxide, fluorocarbon (excludes flammable), and air.

- Permission is required if the processing capacity is 300 m3/day or more for producing Gases specified by a Cabinet Order only.

- Permission is required if the processing capacity is 100 m3/day or more for producing only gases other than Gases specified by a Cabinet Order.

- Permission is required if the total processing capacity of the plant equals or is greater than the figure obtained by the equation specified in the Ministerial Ordinance, for producing both Gases specified by a Cabinet Order and gases other than Gases specified by a Cabinet Order.

- Notification report is required if the processing capacity is below that requiring the permission.

Overview on the regulations relating to Class 1 Producer

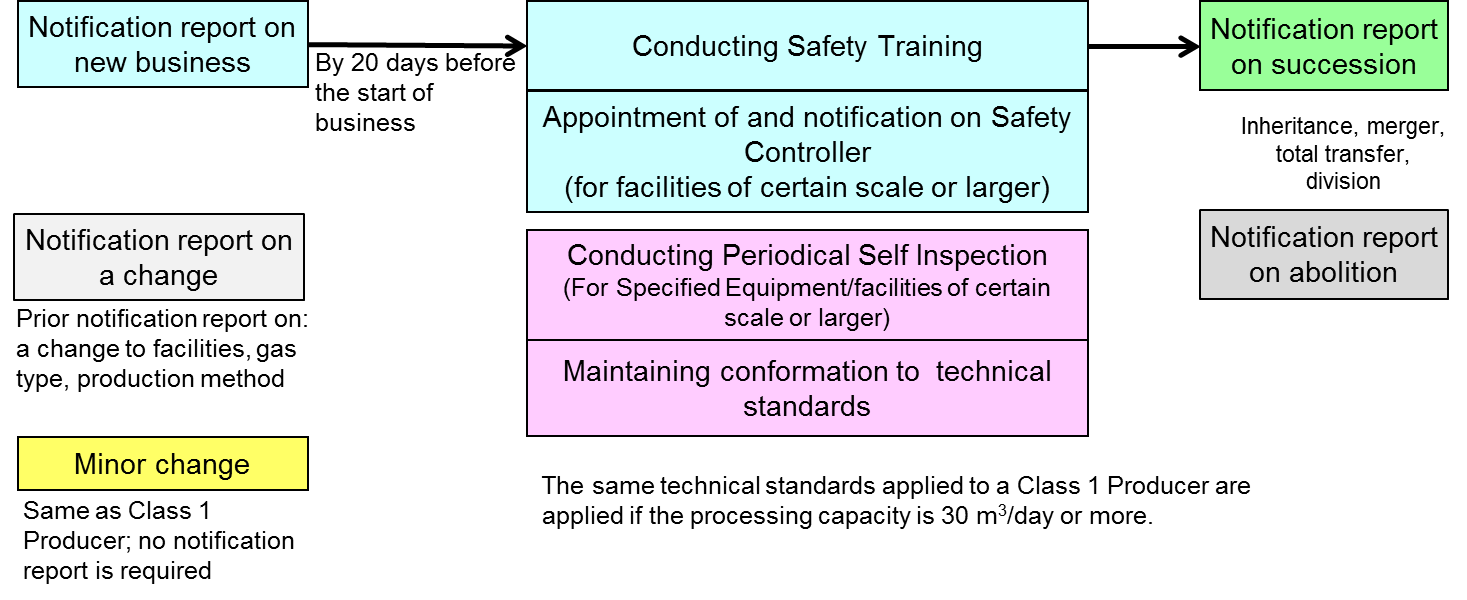

Overview on the regulations relating to Class 2 Producer

The regulations on plants for which a notification report is required for conducting a high pressure gas production business are summarized in the diagram below.

*A notification report is required for a person who is other than Class 1 Producer and who repeatedly or continuously produces high pressure gas (according to the Notification).

Services by KHK relating to the administrative procedures for high pressure gas production

- KHK conducts Designated Equipment Inspections for storage tanks, chemical reactors, heat exchangers, etc., and high pressure gas equipment tests for pumps, compressors, valves, etc. For the equipment that has successfully passed these inspections, a part of the inspection items is omitted at the time of Completion Inspection.

- KHK conducts (preliminary) investigation for accreditation of Accredited Completion Inspection Executor, Accredited Safety Inspection Executor. The Accredited Completion Inspection Executor and Accredited Safety Inspection Executor may conduct inspections on their own.

- KHK has prepared guideline for the Hazard Prevention Rule. Guideline for Safety Training Program is also available.

- KHK offers compulsory training programs that Safety Planning Promoter, Safety Chief, and Supervisory Safety Worker need to take at a certain period.

- KHK offers certification training programs, from which trainees who have completed the program are partially exempt for subjects of national qualification examinations.

- KHK offers training programs of Operation Safety Chief at a place of business that consumes Specified High Pressure Gases.

Overview on the regulations relating to storage of high pressure gas

Categories of the permission and notification report for storage of high pressure gas

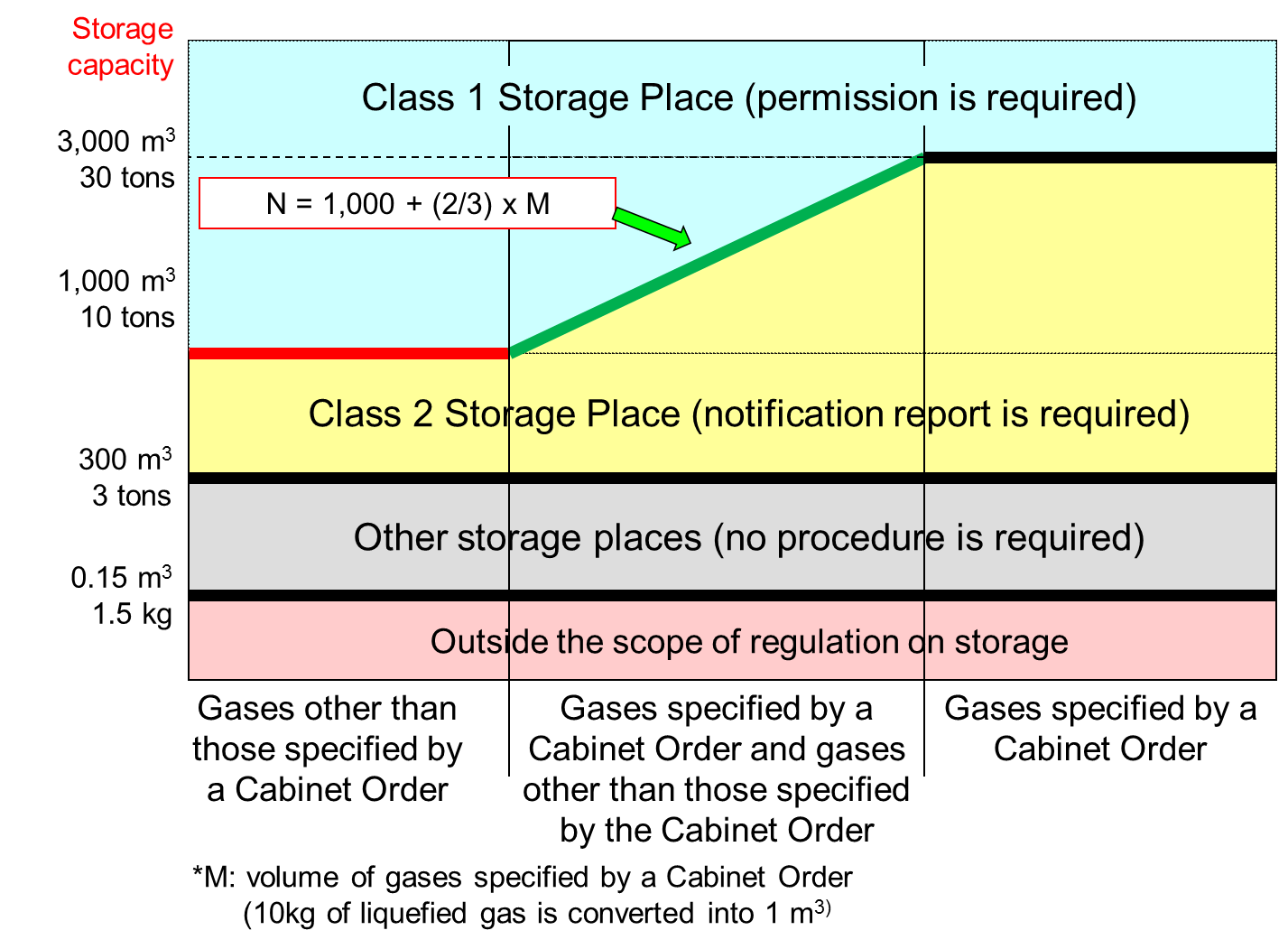

- Gases specified by a Cabinet Order include helium, neon, argon, krypton, xenon, radon, nitrogen, carbon dioxide, fluorocarbon (excludes flammable), and air.

- Permission is required when the storage capacity is 3,000 m3 or more if storing Gases specified by a Cabinet Order only.

- Permission is required when the storage capacity is 1,000 m3 or more if storing Gases other than Gases specified by a Cabinet Order only.

- Permission is required if the storage capacity of the storage place is equal to or greater than that obtained by the equation specified in the Ministerial Ordinance, if storing both Gases specified by a Cabinet Order and Gases other than Gases specified by a Cabinet Order.

- Notification report is required if the storage capacity is below that requiring permission but is 300 m3 or more.

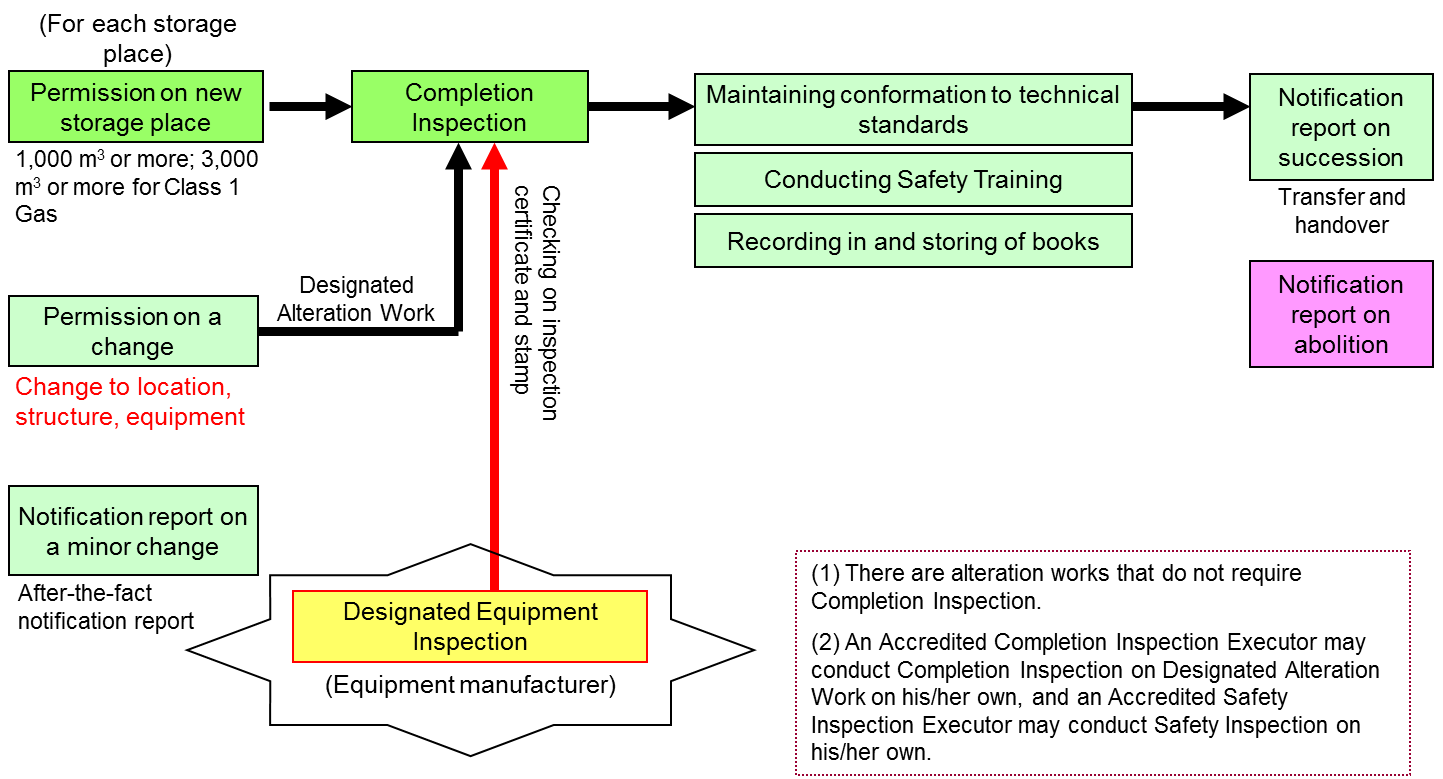

Overview on the regulations for Class 1 Storage Place

The regulations on places of business for which the permission for storage of high pressure gas is required are as summarized in the diagram below.

*Notification report is not required if storage is in relation to production by a Class 1 Producer or on a supply facility or a storage facility under the LPG Act.

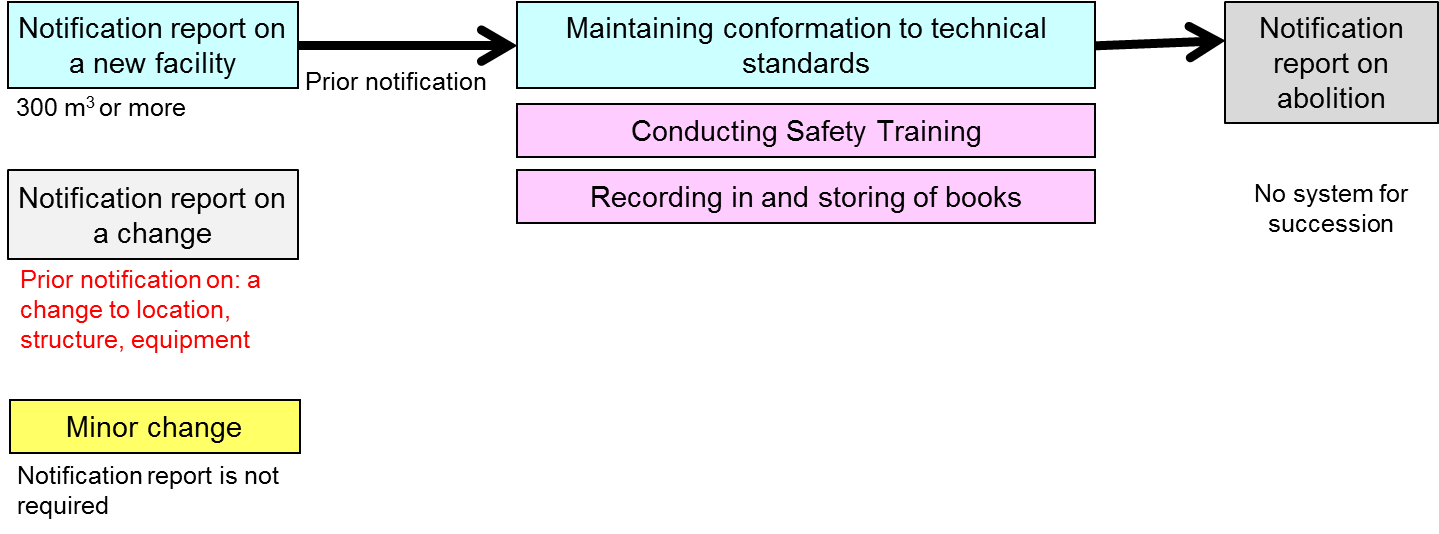

Overview on the regulations relating to Class 2 Storage Place

The regulations on places of business for which notification report is required for storing high pressure gas are summarized in the diagram below.

*Notification report is not required if storage is in relation to production by a Class 1 Producer or on a supply facility or a storage facility under the LPG Act.

*Notification report is not required if the storage capacity is below 300 m3, but conformity to the storage standards is required.

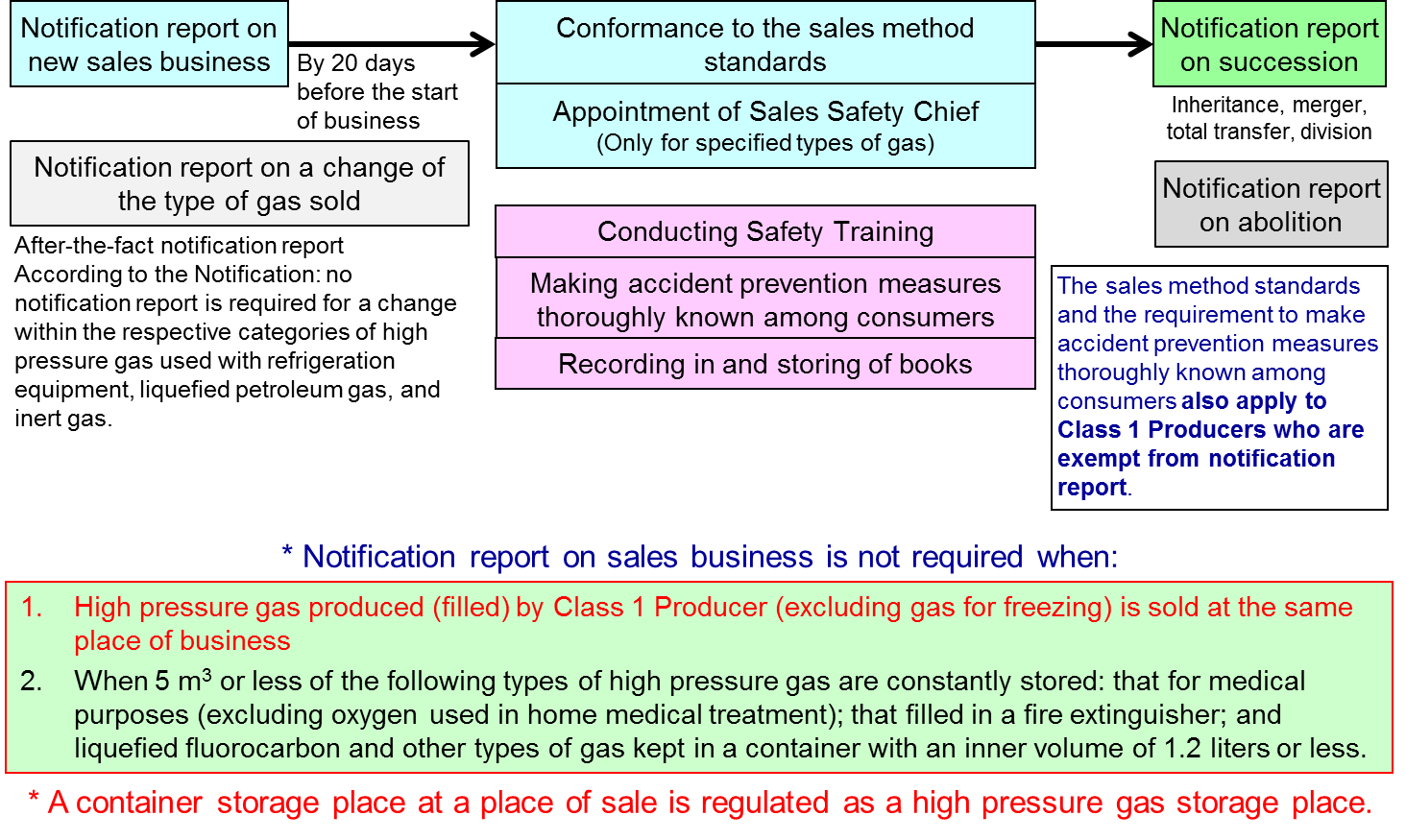

Overview on the regulations relating to sales of high pressure gas

Overview on the regulations relating to high pressure gas Dealers

The regulations relating to high pressure gas Dealers are summarized in the diagram below.

Overview on the regulations relating to consumption of high pressure gas

Overview on the regulations relating to Specific High Pressure Gas Consumer

A person who stores and consumes the types of gas shown below by the quantities shown below or more falls in the category of Specific High Pressure Gas Consumer.

| Type of high pressure gas |

Quantity (storage capacity) |

| Special high pressure gas |

The regulations apply regardless of the capacity. |

| Compressed hydrogen |

300 m3 or more |

| Compressed natural gas |

300 m3 or more |

| Liquefied oxygen |

3,000 kg or more |

| Liquefied ammonia |

3,000 kg or more |

| Liquefied petroleum gas |

3,000 kg or more (10 tons or more except for gas for domestic uses under the LPG Act) |

| Liquefied chlorine |

1,000 kg or more |

*The regulations apply regardless of the storage capacity if the high pressure gas is supplied through a pipeline from another place of business.

*The storage capacity is aggregated only for the facilities connected by piping, and not that of another system.

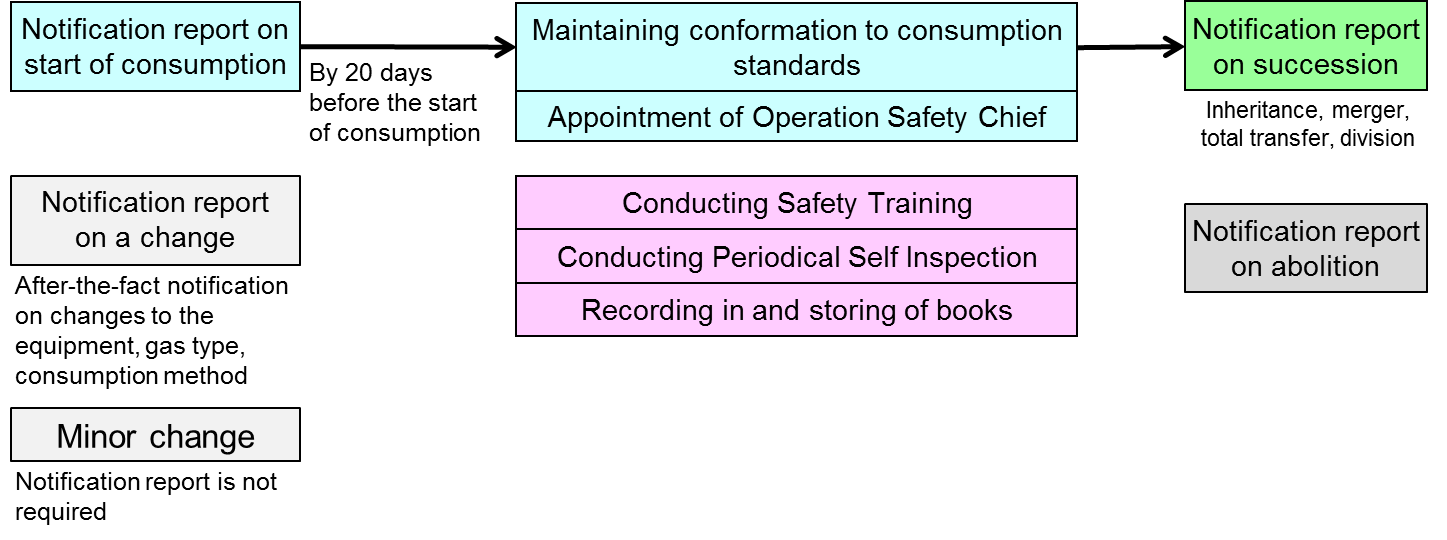

The regulations relating to the place of business of Specific High Pressure Gas Consumer are summarized in the diagram below.

Even if not falling under the category of Specific High Pressure Gas Consumer, gases such as flammable gas, toxic gas, oxygen, and air must be consumed in conformity with the applicable standards.

*The regulations relating to production and storage of high pressure gas apply if the high pressure gas is produced and stored prior to consumption.

*Notification report on consumption is required also when Specific High Pressure Gas is consumed by a Class 1 or Class 2 Producer at a Class 1 or Class 2 Storage Place.

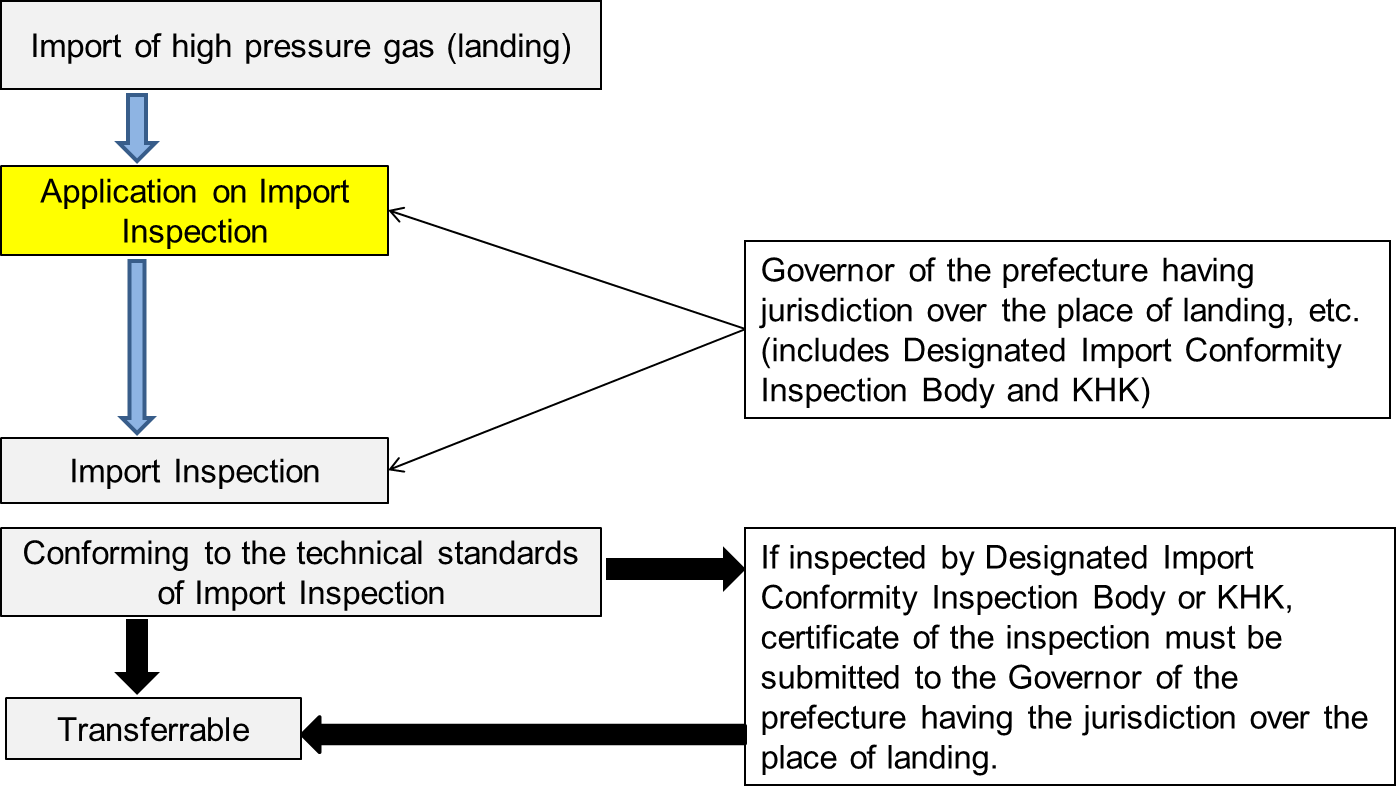

Overview on the regulations relating to import of high pressure gas

The regulations relating to import of high pressure gas are summarized in the diagram below.